The Development of PM2.5 Standard Aerosol Generator Based on PGSS Method

Hu D*, Zhang Z, Guo B, Li B and Bi H

DOI10.21767/2472-1948.100010

1College of Electromechanical Engineering, Qingdao University of Science & Technology, Qingdao 266061, China

2Chemical Measurement Lab, Shandong Institute of Metrology, Jinan 250000, China

3Qingdao Ocean Shipping Mariners College, Qingdao 266071, China

- Corresponding Author:

- Hu D

College of Electromechanical Engineering

Qingdao University of Science & echnology

Qingdao 266061, China.

Tel: 86 10 82388301

E-mail: hudedong@126.com

Received date: March 08, 2016; Accepted date: March 21, 2016; Published date: March 28, 2016

Citation: Hu D, Zhang Z, Guo B, et al. The Development of PM2.5 Standard Aerosol Generator Based on PGSS Method. J Sci Ind Metrol. 2016, 1:10. doi: 10.4172/2472-1948.100010

Abstract

The generation of standard aerosol is of vital importance for the PM2.5 monitors calibration. In this work, a PM2.5 standard aerosol generator with high-pressure mixing kettle, crystal kettle and nozzle was developed based on the Particle from gas saturated solutions (PGSS) approach. The preliminary experiment on the generator showed that more than 90% of the aerosol particles were smaller than 2.5 μm in diameter. This work can provide a theoretical basis for the PM2.5 monitors calibration.

Keywords

PM2.5; Aerosol generator; PGSS; Mixing kettle

Introduction

The standard aerosol generation is important for the PM2.5 monitors calibration. Various techniques are known for aerosol generation such as Atomization method, Fluidized Bed method and Agglutination method [1]. However, the limitations of these traditional methods must be focused that Atomization method could only be applied to powder materials dissolved easily in liquid [2], the Fluidized Bed method is well known for the unevenly distributed aerosol particles [3], and the Agglutination method is only applicable to the particular materials with reaction characteristic [4]. A new approach is therefore needed in the generation of PM2.5 standard aerosol.

The generation of nano-micron particles based on supercritical fluids, especially the PGSS approach, has made a great progress in recent years. PGSS involves first dissolving the supercritical fluid in the molten liquid to form the saturated solution, then spraying saturated solution through the nozzles, causing the nano-micron particles to be generated [5]. With the advantages of the lower operating pressure, less dosage of CO2 and no organic solvent, etc., compared with other supercritical fluids technologies, such as Rapid Expansion of Supercritical Solutions and Supercritical Anti-Solvent [6], PGSS has been widely applied. PGSS was firstly introduced by Weidner [7] in 2003 who chronically committed to the research of the micronization of polyethylene glycol [8,9]. Tandya et al. [10] had generated cyclosporine particles for 1 μm using PGSS. Wang [11] had generated menthol / wax microcapsule from 2 μm to 30 μm. These above showed that PGSS is a better method for the PM2.5 standard aerosol generation with the advantage of controlling the diameter and distribution of the particles by only adjusting the temperature and pressure of the mixing kettle. Therefore, a PM2.5 standard aerosol generation process based on the PGSS was developed, as well as a PM2.5 standard aerosol generator was designed in this paper.

Process of PM2.5 Standard Aerosol Generation

The PM2.5 standard aerosol generator based on PGSS is shown in Figure 1.

Figure 1: Schematic diagram of PM2.5 standard aerosol generator based on PGSS. 1 - CO2 cylinder; 2, 6, 8, 10, 11, 12, 14, 15, 16, 17, 19, 20, 21, 27 - Valve; 3 - Purifier; 4 - Flow Meter; 5 - Refrigeration Equipment; 7 - High - Pressure Pump; 9 - Buffer Kettle; 13 - High - Pressure Mixing Kettle; 18 - High - Pressure Mixing KettleII; 22 - Buffer Kettle; 23 - Flow Meter; 24 - Crystal Kettle; 25 - Metering Pump; 26 - Solution Tank.

1. The CO2 from the CO2 cylinder is fed through the flow system, the value 27 is kept opening to exhaust, and then the CO2 cylinder valve should be closed before the experiment.

2. Materials packed in high-pressure mixing kettle 13 or 18, are heated using the thermostat in a temperature higher than the fusion point of them after a predetermined period of time to melt them.

3. Opening the refrigeration equipment to preset to the cooling temperature, then the relevant valves 2, 6, 8, 10, 11 (or 15) are turned on. The CO2 from the CO2 cylinder passes through purifier, refrigeration equipment, high-pressure pump in turn resulting in a supercritical state, and then flows into highpressure mixing kettle.

4. The supercritical carbon dioxide in high - pressure mixing kettle is maintained at the preset pressure and temperature for 0.5 h to 5 h so as to mix well with the melted materials.

5. Upon opening the valve 16, the supercritical carbon dioxide is introduced through bypass pipeline into the nozzle, then the valve 14 or 19 is turned on that the mixture from highpressure mixing kettle is sprayed through the nozzle with a decompression and expansion, to avoid the blocking in the generation of PM2.5 aerosol, and the supercritical carbon dioxide inside the nozzle designed this work can further mixes with the melted materials, as well as further disperses small droplets. Then the aerosol generated gets through the valve 27 into subsequent equipment.

The PM2.5 Standard Aerosol Generator Design

The PM2.5 standard aerosol generator based on PGSS consisted of the following main components: CO2 cylinders, purifier, refrigeration equipment, and high - pressure pump, thermostat, two high-pressure mixing kettle, crystal kettle, nozzles. The last three components were designed as the main task in this work. This design can meet with the requirement of the temperature and pressure according to Chinese Standards. The others were selected from standard component which could also meet with the experiment requirements.

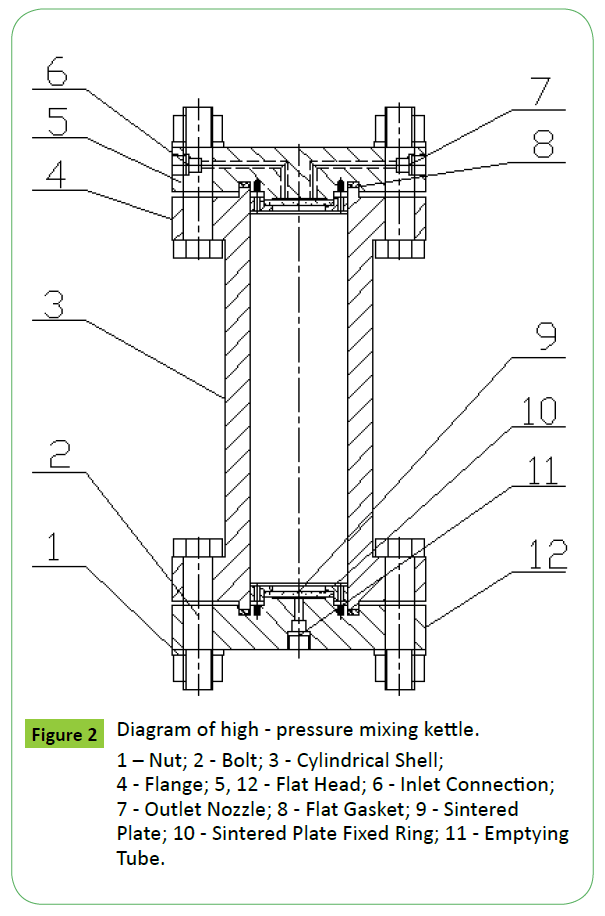

The design of high - pressure mixing kettle

The design parameters of the high - pressure mixing kettle were as follows: maximum working pressure of 15 MPa, maximum design temperature of 100°C, and inner diameter of 30 mm. According to these design parameters, the high-pressure mixing kettle was designed and calculated according to Chinese Standard TSG R0004 - 2012 [12] and Chinese Standard GB150-2011 [13]. The thickness of the shell, the maximum working pressure and the thickness of the head can be calculated using the formula 1 - 3, respectively. The structure of the high - pressure mixing kettle was shown in Figure 2.

(1)

(1)

(2)

(2)

(3)

(3)

Where,δ is shell thickness; Di is inner diameter; [σ]t is allowable stress of material; φ is seam coefficient; pc is design pressure, δe is effective thickness, DG is the center diameter under the pressing force, δp is thickness of the head, and K is structure coefficient of the head (Figure 2).

The design of crystal kettle

The design parameters of the crystal kettle were as follows: maximum working pressure of 15 MPa and inner diameter of 55 mm. The crystal kettle structure was also designed up to China's Nation Standard and Profession Standard [13], for calculating the thickness of the shell and the head obtained from the Equation (1) and (2), respectively, it was shown in Figure 3.

Figure 3: Diagram of crystal kettle. 1 - Flat Head; 2 - Flat Gasket; 3 – Nut; 4 - Stud Bolt; 5 - Sealing Gasket; 6 - Kettle Body; 7, 9 - Supercritical Fluid Inlet Connection; 8 - Mixture Entrance; 10 – Nozzle; 11 - Pressure Strip; 12 – Window; 13 - Sintered Plate Fixed Ring; 14 - Sintered Plate; 15 - Emptying Tube

The design of nozzle

The nozzle shown in Figure 4 is a coaxial three - channel internal - mixing size - adjusting nozzle. The main components of it include the lock nut, seal ring, taper sleeve and core. The taper sleeve was designed according to Chinese Standard JB4732 - 2005 [14]. The thickness of the taper sleeve can be calculated according to the formula 6. The thread stress can be calculated according to the formula 7. The spraying of mixture was a critical step in the generation of PM2.5 aerosol, and the size of aerosol particles was affected by adjusting the nozzle outlet for the clearance size which would decrease as the taper sleeve rising owing to the certain angle between the core and taper sleeve. It meant that different diameters were achieved in one nozzle rather than in several different conventional nozzles. This work not only greatly reduced the number of nozzles and the manufacturing cost, but also was convenient to replace the nozzles frequently during the experiment work.

(4)

(4)

(4)

(4)

Where, Di is the inner diameter of taper sleeve, Do is the outer diameter of taper sleeve, Pc is the design pressure, K1 is load combination factors, Sm is stress intensity, δ1 is the thickness of taper sleeve, σm is the thread stress, and F is axial load.

Manufacturing and Testing of the PM2.5 Standard Aerosol Generator

Manufacturing of the equipment

The PM2.5 standard aerosol generator was manufactured by Nantong Huaan Chaolinjie Co. LTD. High-pressure mixing kettle, crystal kettle and the PM2.5 standard aerosol generator assembled are shown in Figures 5a-5c, respectively.

Testing of the equipment

The experiment was firstly carried out with the high-pressure mixing kettle keeping at 15 MPa and 90°C for 90 min. Then mixture was sprayed through the nozzle into the crystal kettle which was maintained in 5.6 MPa at ambient temperatures keeping the sprayed time for 120 min. In this research, the particles of polyethylene glycol 8000 were generated using PGSS method, collected on the 1000 mesh sieve in Figure 6a, and the Micro-morphology of them was then investigated by the scanning electron micrograph (SEM) shown in Figure 6b.

Subsequently experiment was conducted with the high-pressure mixing kettle keeping at 20 MPa and 80°C for 90 min. Then mixture was sprayed through the nozzle into the crystal kettle which was maintained in 5.6 MPa at ambient temperatures keeping the sprayed time for 120 min. The particles of polyethylene glycol 8000 generated using PGSS method were shown in Figures 7a and 7b.

As shown in Figures 6b and 7b, the particles were small and uniform for overall distribution with more than 90% smaller than 2.5 μm in diameter, and the others were larger than 2.5 μm because a large number of tiny particles aggregated on the mesh sieve in the colleting process. In order to solve the particle aggregation problem, the crystal kettle would be equipped with electrostatic ion-generator to electrify the particles and produce repulsive force so as to overcome the effects of van der Waals forces to avoid aggregation, and the aerosol was directly sprayed into the aerosol spectrometer to detect the aerodynamic diameter of aerosol particles.

Summary

In this paper, the PM2.5 standard aerosol generator based on the PGSS was firstly designed and manufactured. And the results of preliminary experiments, in which the nano-micron particles were generated with polyethylene glycol 8000 as the raw material, showed that more than 90% of the aerosol particles were smaller than 2.5 μm in diameter, this result is similar to the Atomization method with diameter in the range of 1.3 μm - 5.8 μm [1], and the others were larger than 2.5 μm due to the aggregation of tiny particles on the mesh sieve in the collecting process. And further study on the generation process conditions is still required in subsequent experiments to realize steady generation of standard PM2.5 aerosol and make the device as a steady source of PM2.5 aerosol. PM2.5 standard aerosol generator will have great significance for the realization of PM2.5 monitors testing and calibration.

Acknowledgement

The work reported here was supported by the Shandong Institute of Metrology and the Department of Shandong province. We express our grateful thanks to the Science and Technology Development Plan Project of Shandong Province (2014GSF117026) and Project of Shandong Province Higher Educational Science and Technology Program (J13LM08) for their financial support.

References

- Ni SB (1982) Development survey of foreign aerosol generator. Industrial Safety and Environmental Protection1: 34-38.

- Han GL (2011) Micronization of the chitosan blended with essence by a supercritical fluid assisted atomization process. EastChinaUniversityofScienc e and Technology.

- Leeke GA, Lu T, Bridson RH (2014) Application of nano-particle coatings to carrier particles using an integrated fluidized bed supercritical fluid precipitation process. The Journal of Supercritical Fluids 91: 7-14.

- Qiao P, Chen L, Li GT (2010) Method and apparatus of preparing fine particles by using super-critical fluid technology. Pharmaceutical & Engineering Design 1: 35-39.

- Chen H (2007) Ibuprofen and myristic acid microparticles and microcomposites generated by a PGSS process. Xiamen University.

- Hong W (2009) A modified PGSS process: encapsulation of CoQ10 and menthol. Xiamen University.

- Weidner E, Peterman M, Knez Z (2003) Multifunctional composites by high-pressure spray processes. Current Opinion in Solid State & Materials Science 7: 385-390.

- Weidner E, Steiner R, Knez Z (1996)Powder generation form Polyethylene glycols with compressible fluids. High Pressure Chemical Engineering 12:223-228.

- Knez Z (2003) High pressure micronisation of polymers. Proceedings of the Sixth International Symposium on Supercritical Fluids, Versailles 3:1865-1870.

- Tandya A, Dehghani F, Foster NR (2006) Miconization of cyclosporine using dense gas techniques. Journal of Supercritical Fluids 37: 272-281.

- Wang X (2008) Composite ibuprofen/lipid particles by PGSS. Xiamen University.

- Chinese Standard TSG R0004-2012,Supervision Regulation on Safety Technology for Stationary Pressure Vessel.

- Chinese Standard GB150-2011, Pressure Vessel.

- Chinese Standard JB4732-2005, Steel Pressure Vessels- Design by Analysis .

Open Access Journals

- Aquaculture & Veterinary Science

- Chemistry & Chemical Sciences

- Clinical Sciences

- Engineering

- General Science

- Genetics & Molecular Biology

- Health Care & Nursing

- Immunology & Microbiology

- Materials Science

- Mathematics & Physics

- Medical Sciences

- Neurology & Psychiatry

- Oncology & Cancer Science

- Pharmaceutical Sciences